Die Batterieladereichweite hat in der Vergangenheit die Akzeptanz von Elektrofahrzeugen (EVs) durch die Verbraucher in Frage gestellt. Aber innovative EV-Designer haben kreative Wege gefunden, um die Reichweite der Batterie drastisch zu verbessern, und die Elektrofahrzeugindustrie wächst weiterhin in rasantem Tempo, wobei die Akzeptanz von Elektrofahrzeugen deutlich zunimmt. In den letzten zehn Jahren hat sich die durchschnittliche Reichweite von Batterien von Elektrofahrzeugen nach Schätzungen mehr als vervierfacht. Diese Leistungssteigerung bringt zentrale thermische Herausforderungen mit sich. Die zunehmende Akzeptanz von Elektrofahrzeugen erhöht den Bedarf an robusteren EV-Batteriedesigns, um die Lebensdauer zu verlängern und Garantieansprüche zu kontrollieren oder zu reduzieren.

Das innovative Team aus Experten und Designleitern von Boyd steht bei der Lösung dieser Herausforderungen an vorderster Front. Wir helfen Pionieren in diesem Bereich, Innovationen zu beschleunigen. Unsere Ingenieure entwickeln integrierte thermische und technische Materiallösungen, die kleinere, robustere, leichtere, effizientere und zuverlässigere Batterien mit schnelleren Ladezyklen für eine größere Reichweite, Sicherheit und Zuverlässigkeit von Elektrofahrzeugen ermöglichen.

Thermisches Durchgehen?

Lithium-Ionen-Thermal-Durchgehen tritt auf, wenn die von einer Batterie erzeugte Wärme die abgeführte Wärmemenge übersteigt. Unkontrollierte Hitze kann eine unkontrollierte Kettenreaktion auf umgebende Batterien und Lithium-Ionen-Batteriezellen auslösen. Wenn das thermische Durchgehen von Lithium-Ionen nicht richtig gehandhabt wird, überhitzen Batterien, erzeugen Rauch und verbrennen.

Mehrere Faktoren verursachen ein thermisches Durchgehen, darunter interne und externe Kurzschlüsse, Überladung, hohe Umgebungstemperaturen, schnelle Zyklen und Batteriealterung. Ein effektives Wärmemanagement ist nicht nur für die Batterie eines Elektrofahrzeugs, sondern auch für die Sicherheit der Fahrzeuginsassen von entscheidender Bedeutung.

Wie kann man ein thermisches Li-Ionen-Durchgehen verhindern? Thermisches Durchgehen der Batterie

Müssen Sie robust sein?

Raue Umgebungsbedingungen sind für Elektrofahrzeuge alltägliche Realität. Batterien und Komponenten für Elektrofahrzeuge müssen während des Betriebs geschützt werden, um die Lebensdauer zu verlängern und Garantieansprüche zu reduzieren. Robuste EV-Batterien können Kollisionen, anhaltenden Stößen und Vibrationen, extremen Straßenbedingungen und extremen Wetterbedingungen standhalten und eine bessere Leistung erbringen.

Wie schützt man EV-Batterien?

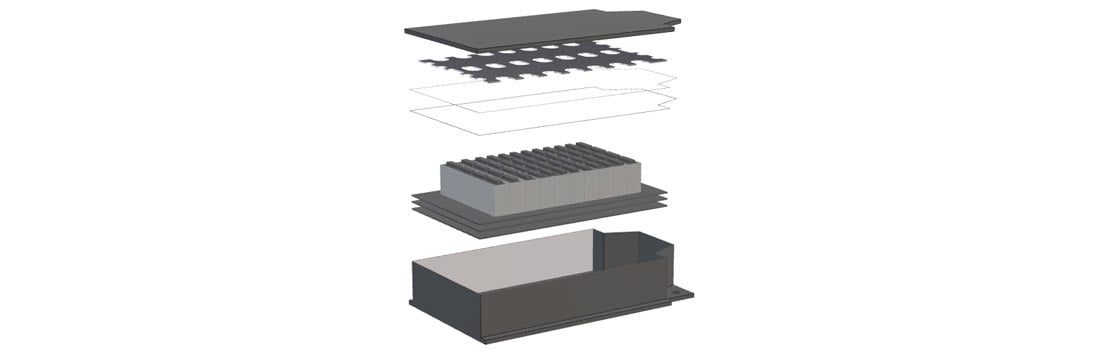

Batteriezelle und Batteriemodul

Verbessern Sie die Batterieleistung, -sicherheit und -zuverlässigkeit mit EMI- und RFI-Abschirmung. Die EMI-Abschirmung verhindert sowohl den Ein- als auch den Ausgang von Hochfrequenzstörungen (RFI), elektrostatischen Interferenzen (ESD) oder elektromagnetischen Interferenzen (EMI), die alle in komplexen elektrischen Systemen in Elektrofahrzeugen weit verbreitet sind. EMI-Abschirmungen von EV-Batterien schützen die Batterieleistung und verhindern elektronische Fehlfunktionen in kritischen Sicherheitssystemen. Die leitfähigen Schäume, Elastomere, Klebstoffe, Folien und mehr von Boyd wurden entwickelt, um diese Interferenzen zu mindern und unerwünschte Signale abzuschirmen, wodurch die Zuverlässigkeit und Effizienz von EV-Batterien verbessert wird.

Wickeln Sie EV-Batteriezellen mit elektrischer Isolierung ein

Dielektrische Klebstoffe auf Sammelschienen

Kühllösungen für EV-Batterien müssen den Herausforderungen der Hitze und den allgemeinen Designanforderungen gerecht werden, dürfen jedoch kein zusätzliches Gewicht oder Volumen hinzufügen, um die Ladereichweite der EV-Batterie zu erhalten. Leichte Batterie-Flüssigkeitskühlplatten bieten eine robuste strukturelle Unterstützung (RSS) und maximieren die Wärmeabfuhr der Batterie für die leistungsstärksten Batteriemodule und -packs von Elektrofahrzeugen von heute. Flache Kühlplatten kühlen Batterien effizient und schaffen zusätzlichen Designraum im Batteriefach, wodurch Platz für größere, leistungsstärkere Batterien geschaffen wird.

Die kundenspezifischen Kühlplatten für EV-Batterien von Boyd optimieren die interne Geometrie, um die turbulente Strömung zu maximieren, und die äußere Geometrie mit Skylines und Sockeln, die an Ihr Batteriedesign angepasst sind, um den Kontakt mit der Wärmequelle und die Wärmeableitung zu maximieren. Die Batterie-Flüssigkeitskühlplatten von Boyd verfügen über hundertprozentige thermische Inline-Tests und jahrzehntelange bewährte Marktleistung, um die Zuverlässigkeit zu gewährleisten.

Verbessern Sie die Wärmeübertragung zwischen der Batteriekühlplatte und dem Batteriemodul, indem Sie den Wärmewiderstand zwischen diesen beiden Oberflächen minimieren. Thermal Interface Materials (TIMs) minimieren den Wärmeflusswiderstand zwischen Oberflächen und leiten die Wärme effizienter von empfindlichen EV-Batterien durch die Batteriekühlplatte in das Flüssigkeitskühlsystem ab.

Die wärmeleitenden Klebebänder, Gap-Filler, Wärmeleitpads, Folien, Phasenwechselmaterialien und Wärmeleitpasten von Boyd maximieren die Leistung des Batterieflüssigkeitskühlsystems, indem sie die Wärme effizienter von der Batterie auf die Flüssigkeitskühlplatte übertragen.

Ganz gleich, ob es um den Schutz und die Kühlung von EV-Batterien, die Entwicklung intelligenter Displays und Telematik, die Optimierung des Ladens von EVs, die Verbesserung der Markenidentität von EVs und vieles mehr geht, Boyd hilft E-Mobility-Designern und Marktführern, Innovationen zu beschleunigen. Weitere Informationen zu den EV-Batterielösungen von Boyd finden Sie in unserem Video unten. Bei spezifischen Fragen zu Ihrer Anwendung wenden Sie sich an unsere Experten.