Bezel Bonding and Display Gaskets for Integrated Electronics

Modern display technologies face numerous design challenges. Current trends include the integration of high-end components and sensors, durability enhancements, edge-to-edge display technologies and device miniaturization. Effective product launch of these modern display technologies reflects the assembly as a whole, and bezel bonding and display gasket materials must be selected based on application performance requirements to meet design specifications.

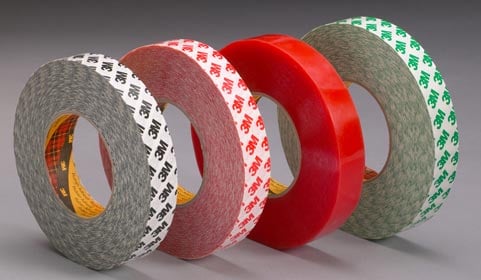

VHB™ Tapes address the demands of a wide range of bezel bonding and display gasket applications. These high-strength, doublesided acrylic foam tapes are formulated to achieve application specific characteristics, but they can also carry complications along to the converting process due to die cut dimensions and narrow bond lines. Softer tapes can be challenging for rotary die-cutting processes, and to obtain a die-cut integrated display gasket solution that adheres to required tolerances, original equipment manufacturers require a solutions provider with advanced converting capabilities.

Boyd is one of the largest global preferred converters. They have the ability to provide their customers with zero tolerance die-cut components, cleanroom manufacturing facilities, segmented manufacturing technologies and highly automated reel-to-reel manufacturing.

VHB™ Tapes for Bezel Bonding And Display Gaskets

These tapes lead the market with a portfolio of high-strength, double-sided acrylic foam tapes. The VHB™ Tape product line is a family of closed-cell, acrylic foam tapes with high performance adhesives and each tape is formulated to achieve a balance of properties that address specific performance requirements.

- Edge-to-edge display technologies have ultra-thin bond lines and require tapes with excellent peel strength, impact resistance and energy absorption

- Larger displays require bonding tapes that are resistant to creep with greater shear strength

- Automotive displays require durable bonds that resist vibration fatigue and impact stress

- Industrial or agricultural interfaces often require water-tight seals and durability enhancements

VHB™ Tapes are inherently viscoelastic in nature and exhibit a high degree of energy absorption and stress relaxation. Applied stress is distributed evenly across the entire bond area, limiting the amount of force that gets exerted on display components. This acts to protect the electronic display. The closed-cell foam structure seals out contaminants, moisture and solvents. These tapes are available with highly conformable, conformable, and firm adhesive foam cores, acrylic and modified acrylic adhesives and serval different release liners in a rand of thickness and colors.

VHB™ Tape 59XX Series

The VHB™ Tape 59xx Series encompasses a wide range of high performance bonding tapes that fulfill most bezel bonding and display gasket applications. These tapes are available in a thickness range from 150 µm to 1,6 mm. They are supplied with a modified acrylic adhesive on both sides of a very conformable adhesive foam core, providing good adhesion to the widest range of substrates, including most powder coated paints and many plastics. These are the go-to tapes for most electronic display bonding applications.

VHB™ Tape GPH Series

The VHB™ Tape GPH Series is the newest product line in the VHB™ Tape family. These tapes address the requirements of demanding high temperature applications and are suitable for assembly prior to painting or powder coating operations that have high temperature bake cycles. They provide a fast-setting, high-strength permanent bond with longterm durability, eliminating the need for mechanical fasteners or liquid adhesives.

Thicker tapes like VHB™ Tape GPH-160GF, are suitable for bonding dissimilar substrates. This tape is a grey, 1,6 mm thick, double-sided acrylic foam tape with a red polyethylene liner.

Selection Criteria

Designed for longevity, VHB™ Tapes are selected based on design criteria including display size, weight, bond width, position of the display and thickness. Proper selection of materials ensures a durable long-lasting bond.

Thickness

Tape thickness is selected based on the size and rigidity of the bonded substrates and their flatness. Thicker tapes provide an improved bond strength when mating irregular and larger surfaces. Rigid substrates with normal flatness are best handled by a tape thickness of 1,1 mm or greater, while flexible and flatter surfaces are most suitable for thinner tapes.

Tape Usage Requirements

The durability of VHB™ Tapes is a function of design proportions. Due to their viscoelastic nature, care should be taken to specify an adequate amount of tape for bonding applications. To best avoid creep and premature failure, 4 in 2 of tape should be used for every 1 lb of weight supported under static loads.

Core Firmness

As a rule of thumb, firm core tapes are most suitable for addressing flat substrates, while larger and curved displays are best suited for softer conformable core tapes. The softer conformable adhesive cores also provide for enhanced impact resistance and have become the go-to products for most mobile electronics applications.

Boyd: Integrated Display Gaskets and Bezel Bonding Solutions

Boyd addresses the requirements of advanced display technologies. They provide their customers with multifunctional components including integrated display gaskets and bezel bonding solutions, where local secondary applications are optimized by including in the original design. Boyd can pull close proximity die cuts into the bezel solution for a one-pass, multi-layered, multisolution deliverable, such as a microphone or speaker gaskets, display ring tape, spacers and dampers. These multifunctional components are produced in a clean room environment and assembled via segmented frame technology, capabilities that allow Boyd to deliver contaminant and particulate-free, ultratight tolerance die-cut components at the lowest cost possible.

Optically Clear Adhesives (OCA) Conversion Capabilities

Boyd’s display technologies utilize sheet-type optically clear adhesives (OCA) when bonding visually clear components, such as touch screens, graphic overlays and polymeric film glass laminates. Sheet-type OCA addresses inherent limitation that can affect screen brightness, contrast ratio and the durability of these die-cut integrated display gasket solutions.

Sheet-type OCA is an alternative to optically clear resins (OCR) or liquid OCA (LOCA). Liquid adhesives are applied in a fishbone pattern prior to lamination and a UV curing process. These adhesives are prone to leakage and users may experience uneven curing defects that can affect product quality and yield rates.

Light transmittance also decays as incremental materials are stacked upon each other, and to eliminate any amount of light reflection or refraction, an adhesive of uniform thickness with a refractive index closely matched to mating components is applied between each medium.

Boyd's integrated die-cut components are assembled with a sheet-type OCA that has a refractive index between 1,4 and 1.5, which is close to that of display films, filter or even touch panels. OCAs are dimensionally stable, exhibit low shrinkage, resist whitening, and reduce any amount of reflection between each substrate in the finished component. Boyd's expertise in converting OCAs allows them to further reduce material costs, maintain high manufacturing yields while improving screen contrast and brightness by as much as 8 %. Their inventory of OCA materials is inclusive of 3M™ 821X Optically Clear Adhesives. These highly cohesive acrylic OCAs are available in a thickness range of 1 to 5 mils. They offer superior clarity with internal light transmittance greater than 99 % and excellent adhesion for reliably bonding most transparent substrates.

Segmented Frame Technology

Segmented frame technology is a high precision reel-to-reel manufacturing principle. Boyd's proprietary production lines utilize this concept to eliminate waste and optimize the value of stock materials. Waste is eliminated by orienting release liners, bonding tapes, optical films and optically clear adhesives in such a manner that material utilization is optimized, driving down operational costs.Cleanroom Capabilities

Problematic foreign object debris (FOD) gives rise to costly defects that affect production yield rates and product performance. Boyd's rotary die-cutting production lines are housed in class 100 to class 100.000 cleanroom facilities. This allows Boyd to manufacture highly sensitive, contaminant and particulate-free multifunctional display bonding solutions.

Inspection Equipment and In-Process Quality Checks

Segmented frame technology is a high precision reel-to-reel manufacturing principle. Boyd's proprietary production lines utilize this concept to eliminate waste and optimize the value of stock materials. Waste is eliminated by orienting release liners, bonding tapes, optical films and optically clear adhesives in such a manner that material utilization is optimized, driving down operational costs.

Conclusion

Boyd sources the highest quality display gasket materials from the most reputable material solutions providers in the industry. Cutting edge products, like VHB™ Tape GPH series, are converted in a cleanroom environment, utilizing advanced rotary die-cutting methods to deliver multifunctional components that seal out moisture and ingress, provide impact and vibration resistance and maintain optical clarity while adhering to ultra-tight tolerances. Boyd's advanced converting allows them to produce bezel bonding and display gasket solutions for a host of integrated electronics applications. Contact us and learn how we can assist with advantage by co-developing and fabricating a custom integrated display gasket solution that addresses budget and design requirements.

Have questions? We’re ready to help!